2023-09-01

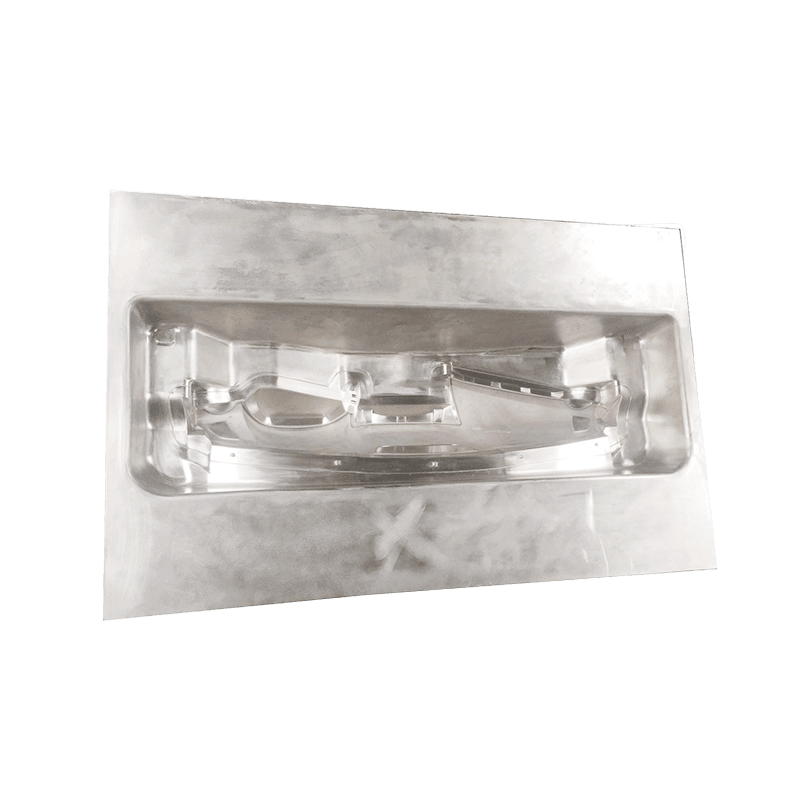

This process uses closed two-sided moulds and a low pressure injection to force the resin into the mould. In some specialized RTM processes, a vacuum is used to assist the resin injection process. This helps to facilitate the flow of the resin through the layup and to eliminate trapped air. Depending on the material used for the RTM mould, it can be made of steel, aluminium, or composite materials.

Resin transfer moulding is a process that uses a metal mold to mold a composite preform. The mould is then filled with liquid resin under hydrostatic pressure. The final part is then cured using hydrostatic pressure. During this process, the moulds are designed with dimensional accuracy in mind. They can also be equipped with metallic inserts or pre-cured details. During the RTM process, the mould is closed.

A custom RTM mould is a tool used in RTM processes. It is a process that allows for virtually any reinforcing material and catalyst blend. The process is a manual process and requires tools, such as a cavity and core, which are made from steel or aluminum. Several factors determine the best RTM mould for a specific part, including the material and shape. This is the most important consideration for a Custom RTM mould.

A Custom RTM mould is made to the specifications of a company. They provide the customer with a custom RTM mould, which is a customized part that was created by an expert. This type of mold is typically made of steel or aluminium and is highly accurate and durable. The process is also manual, and there are no tools involved. However, if a customer wants a specific product, they can provide an RTM mold that meets their requirements.

The RTM process is a manual process where the resin is injected into a mould. In this process, the mold is closed, and low-pressure resin is forced into it. The process can be manual or automated, and it uses a vacuum to help the process. The process of Custom RTM moulds is manual, and it involves five phases: prep work, reinforcement, and the resin injection. The resin curing stage is a time-consuming procedure.

The process of RTM moulds is manual and flexible. Almost any type of reinforcing material can be used in this process. You can control the amount of styrene released from the molds. In addition to a manual process, this method of RTM moulds can be automated as well. It is an efficient way to manufacture a part that resembles a physical component.

The RTM process uses a closed mould to transfer resin from the resin to the mould. The resin is forced into the mould from a central core into a cavity. The moulds are usually made of steel or aluminium. The process is manual. It can also be done in automated mode. It is possible to use different types of reinforcing materials and the catalyst. Forcing the resins into the mould is the most efficient way of reducing styrene emissions in a production workshop.

The RTM process is a closed moulding process. This process is used in manufacturing high-performance composite parts. It involves a series of steps, which are all dependent on the type of resin used. The first step of RTM moulding is the injection of resin. Once the resin is injected into the mold, it reaches the desired temperature. Once the part is completed, the tool is opened and the part is ready for paint.

English

English 简体中文

简体中文