2023-09-01

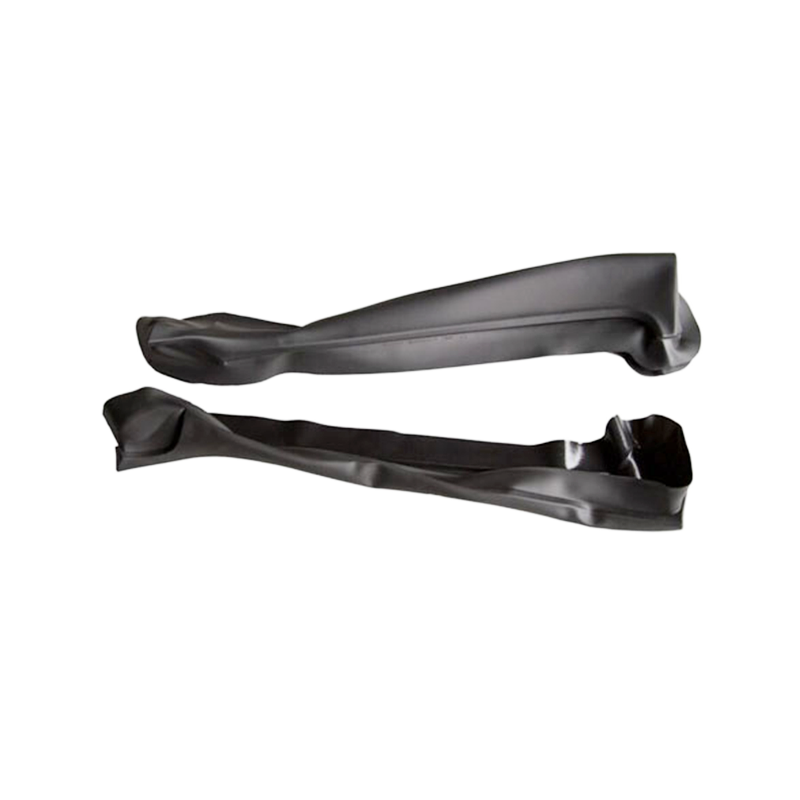

PDCPD Mold technology revolves around the unique characteristics of PDCPD resin, a thermoset polymer renowned for its exceptional mechanical properties. The process begins with the careful selection of PDCPD resin, which is then injected into a precisely engineered mold. Once inside the mold, the resin undergoes a curing process, transforming it into a solid state that faithfully replicates the mold's design. This innovative molding technique allows for the creation of components that exhibit a remarkable balance of strength, impact resistance, and chemical resilience.

Strength and Durability: The Hallmarks of PDCPD Molded Components

One of the standout features of PDCPD Mold technology is the exceptional strength and durability of the components it produces. PDCPD resin boasts impressive mechanical properties, including high tensile strength and impact resistance. This makes PDCPD Molded components ideal for applications where structural integrity is paramount, such as in the automotive and transportation industries. Whether it's intricate engine covers or robust exterior panels, PDCPD Molded components deliver the strength needed to withstand demanding conditions.

Versatility Redefined: Complex Geometries and Design Freedom

PDCPD Mold technology offers a level of design versatility that was once considered challenging to achieve. The injection molding process allows for the creation of complex geometries, intricate textures, and detailed features that are essential for products in various sectors. From aesthetically appealing consumer goods to functional industrial parts, PDCPD Molded components break the barriers of traditional manufacturing, enabling designers to push the boundaries of creativity and innovation.

Corrosion Resistance and Chemical Resilience

Industries dealing with corrosive environments or exposure to chemicals have found a reliable ally in PDCPD Mold technology. PDCPD resin naturally resists corrosion, making it an ideal material for components used in challenging conditions. Whether it's chemical storage tanks, industrial enclosures, or agricultural equipment, PDCPD Molded components offer robust protection against corrosive agents, extending the service life of products and minimizing maintenance requirements.

Lightweight Solutions: Enhancing Efficiency and Sustainability

In industries where weight reduction is a priority, such as aerospace and transportation, PDCPD Mold technology shines. The lightweight nature of PDCPD resin, coupled with its impressive strength-to-weight ratio, enables the creation of components that contribute to overall efficiency. Lighter components lead to reduced energy consumption, improved fuel efficiency, and lower environmental impact – aligning with the global drive toward sustainability.

English

English 简体中文

简体中文