2023-09-01

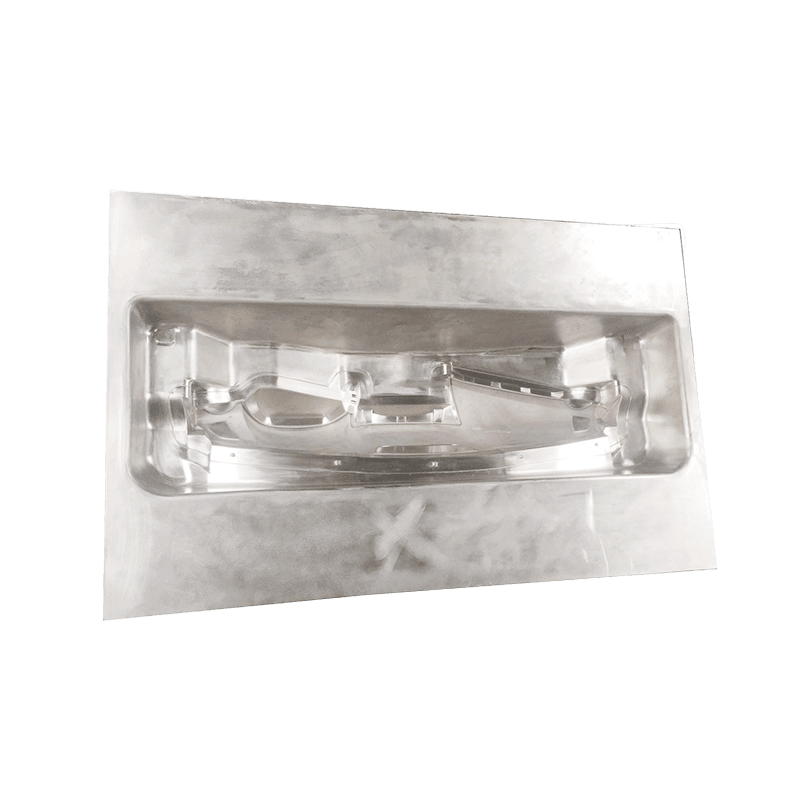

The manufacturing process of RTM involves the use of closed moulds, which are made from matched metal tools. After inserting a preform, the mould cavity is closed and the resin is injected. To remove the part, the tool can be opened and the part can be removed. This method is the most economical and convenient way of manufacturing complex composite parts, such as automotive components. Despite its high price, custom moulds are the perfect solution for complex and large-scale manufacturing.

When designing Custom RTM Moulds, consider your requirements for the mould. Are you manufacturing complex parts? Do you want to use high-quality materials for your parts? Do you need a high-volume production run? Then you may want to make sure your tools are well-suited for the material and the part's shape. By working with a custom mould maker, you can get the best of both worlds and maximize your production efficiency.

RTM moulds are a vital component of a successful production run. They are essential for ensuring that the end product has the right shape and size. Depending on the application, custom RTM moulds can be made of high-grade steel or aluminium. The process can take several weeks. A custom mould can be produced at any time. During the entire process, your customers will appreciate the high quality of your final product.

The RTM process is manual and uses various materials to make a part. With RTM, the material used to make a mould is poured into the resin and hardens. A custom mould is a key component of the manufacturing process. A good custom mould will provide your customers with a unique product that will meet their specifications. There are many advantages to RTM, and they are also the best option for large-scale manufacturers.

Custom RTM moulds are designed and manufactured for large-scale manufacturing. They are designed and manufactured by experienced moldmakers. Creating custom moulds is not difficult and is an excellent option for companies that need high-volume production. Besides, RTM moulds are also a great way to save money on moulding. You can use these moulds to make a variety of different products. The possibilities are endless.

Custom RTM moulds are made from aluminium or steel. A custom mould can be designed to fit any product. They can also be designed to fit your specific needs. Whether you need a small custom mold or a large scale custom RTM mould, you'll be able to find a solution for your needs. A quality mould will not only last longer than an ordinary mould. These can be made to be used over again.

If you need a custom mould, you can design the mould to meet your requirements. The process of custom mould manufacturing has many advantages. A customized RTM mould can be made in minutes and can be manufactured in a wide range of materials. If you have a large production, custom RTM moulds are an excellent option. They can produce parts in a wide range of different materials. The advantages of using the RTM process include the following:

A custom RTM mould is made by a manufacturer to match the product. The mould is a metal tool, which is then inserted into a cavity before the resin is pumped in. Once the fibre preform is placed in the mould cavity, it is closed and resin is pumped into the tool. Afterwards, the tool is opened and the part is removed. The RTM moulding process is manual, requiring a mold made of steel or aluminium.

The RTM process uses highly versatile materials, including composites. Almost any type of reinforcing material can be used to manufacture a custom mould. It can also be used to co-cure foam, metallic inserts, and pre-cured details. The process of RTM is manual, but it offers high quality parts that are made to last. If you have an existing mold, you can choose from an existing design or create one from scratch.

English

English 简体中文

简体中文