2023-09-01

In the following content, we take several major fields as examples to show you the vigorous development of PDCPD products.

Application 1. After the UAV uses PDCPD material parts to replace the original parts, the self-weight of the UAV is reduced from 2.6kg to 1.13kg, and the flight effect and endurance are significantly improved. Moreover, due to the excellent electrical properties of the PDCPD material, the remote control performance of the aircraft after the replacement is roughly equivalent to that of the original accessories. Except that the propeller still needs to use carbon fiber material, other airframe structural parts can be replaced by PDCPD material accessories.

Application 2, PDCPD products of medical instruments have low thermal conductivity and high electrical insulation. After adding certain flame retardants, they can also meet the national flame retardant regulations for indoor plastics. Based on this feature, PDCPD materials can provide a guarantee for the innovative development of medical devices in my country.

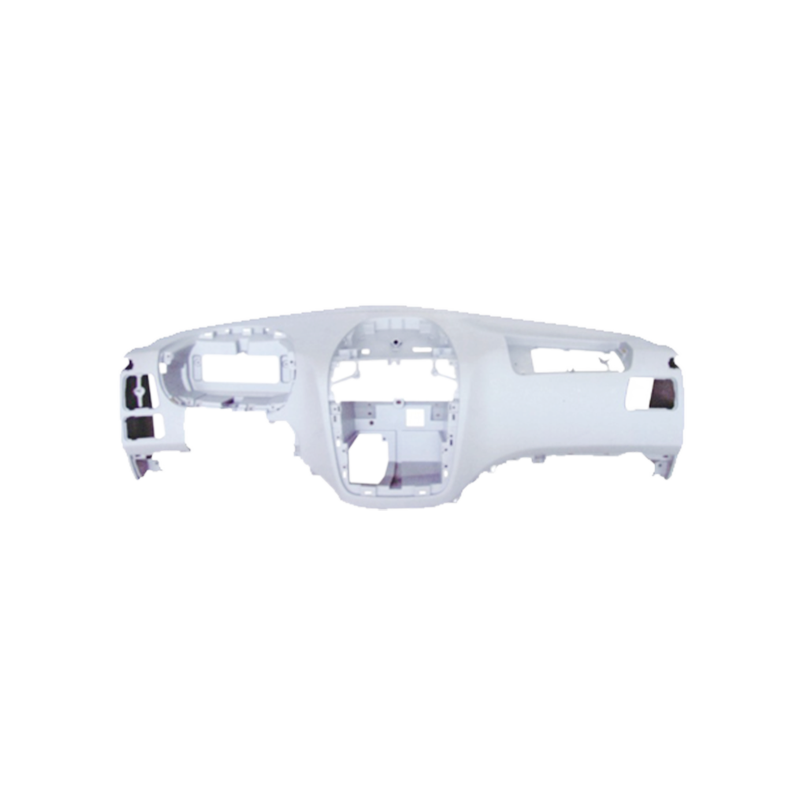

Application 3: Auto parts made of PDCPD materials can be used to replace traditional metal parts. While ensuring the strength and durability of accessories, it can also greatly reduce the weight of the car and reduce fuel consumption.

The above three fields are the main application fields of PDCPD products. Naturally, this new material has other detailed applications. We will continue to introduce it to you in the following content.

English

English 简体中文

简体中文